One common Power Commander install issue

Posted by Kenny Martin on 7th Dec 2020

If you’re changing the exhaust, intake or engine design on your motorcycle installing Dynojet’s Power Commander can help you change the fuel delivery so your bike can run it’s best. Dynojet’s Power Commanders have been around for a long time and probably the motorcycle industry standard for a piggyback fuel control module. There are a couple common problems that we see all the time when customer attempt to install a power commander.

The most common issue we see when a customer comes into our shop to have a custom map built is the simple connection to the engines throttle position sensor. It’s actually two problems, but they both deal with hooking into the same sensor. You see a power commander changes fuel delivery based on two primary engine data. Throttle position and RPM. The power commander must know what throttle position the bike is currently at and what RPM, then it references a predetermined table “MAP” and selects the proper fuel change for that throttle position and RPM. Simple right? Sometimes. The problem lies in that the power commander can only give the proper fuel delivery if it has the proper throttle position reading and rpm. In most cases we see that the power commander throttle position reading is either hooked to the wrong sensor, or the connection method “T-Tap” has worn and the power commander isn’t reading the bike’s throttle position anymore.

First, a lot of motorcycles have two throttle position sensors on them. This was the case until the ride-by-wire motorcycles started to come out, but that’s another story. You see, the RPM range on a motorcycle is usually excessively big. Inline four cylinder motorcycle engines, depending on cc’s, normally rev to 10k rpm. Some 600cc motorcycles even rev to 16,000 rpm. Because of this broad rpm range, and others, these engines can only accept a given amount intake air for any given rpm range to provide a linear power curve. This phenomenon is typically up to a certain point of the engines rpm. Engines that rev’s to 10k this point may be around 5k. For an engine that rev’s to 16,000 RPM this can be around 9k rpm. If a rider were to give the bike full throttle (twist the throttle grip wide open) below this point the engine design cannot make use of that extra air at this lower rpm. To correct this manufactures install a second set of throttle blades (butterflies) in the throttle body, above the one operated by the rider, to only allow the max amount of air an engine can accept for a given rpm. These extra plates, or butterflies, are called secondary throttle plates (STP). They are always located directly above the throttle plate that is controlled by the throttle grip (rider). So, for example, if a rider turns the throttle to wide open (100%) at 3000 rpm the engine management system may only open the secondary plates to about half 50% open. This 50% opening is the max air that engine can handle to make the best performance at that rpm. If the manufacturers didn’t do this and a rider twisted the throttle wide open the engine might bog, be sluggish, and or spit and sputter. Sometimes this decrease in power isn’t even noticeable to a normal rider but can be seen when an engine is on a dyno.

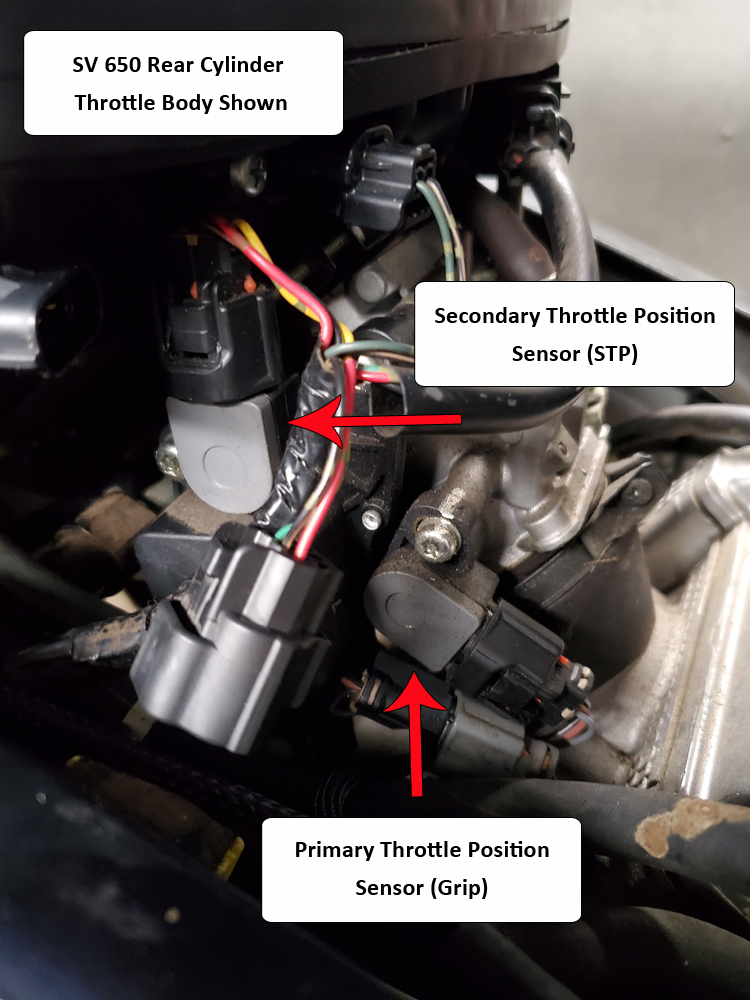

Now that you know a bike has 2 sets of throttle plates, and why, you can almost guess what the common problem we see is. Yup, you guessed it, the Power Commander is hooked up to the wrong throttle position sensor. Instead of tapping into the throttle position controlled by the throttle grip, what the Power Commander is looking for, the Power Commander is hooked into the throttle position sensor monitoring the secondary throttle plates. Looking at the image attached to this thread you can see how easy of a mistake this can be. In this picture of an SV650 you can see the top throttle position sensor for the secondary’s and the bottom throttle position sensor for the actual grip throttle. Both have the same connector, only the bottom sensor is the one that the power commander needs to monitor to deliver the proper fuel in it’s preprogramed fuel table.

If you have installed a Power Commander and your motorcycle doesn’t seem to be running as good after you did, check this sensor connection and make sure you don’t have it connected to the wrong throttle position sensor.

Questions or comments can be directed to kenny@mrpmotorsports.com